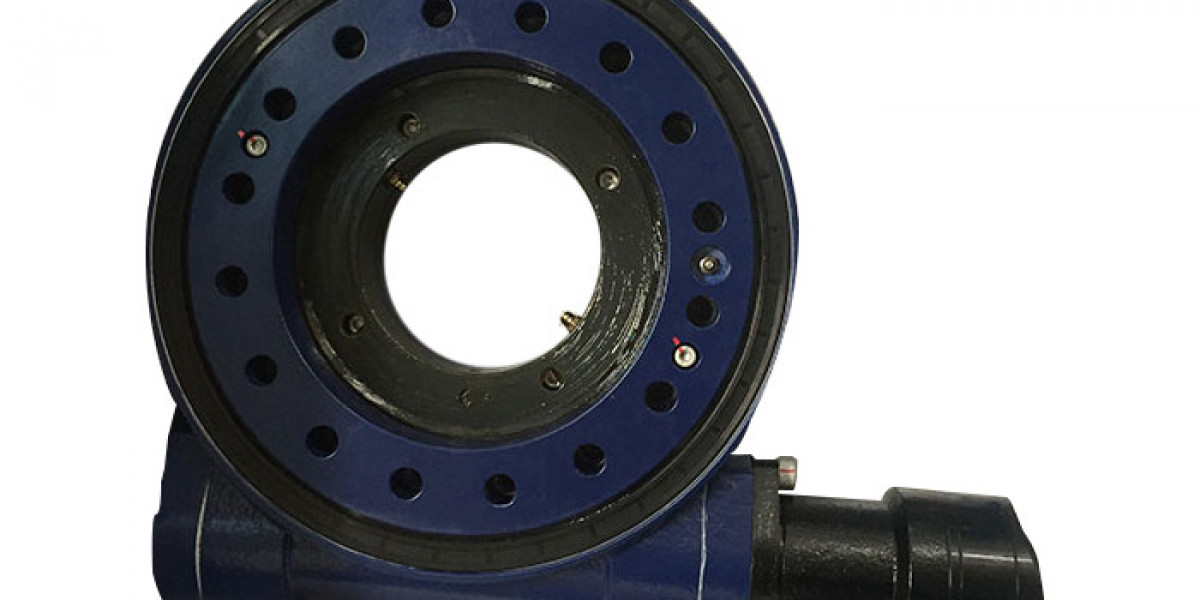

In line gearboxes, also known as parallel-shaft gearboxes, are widely used in industrial and mechanical applications due to their simplicity, reliability, and efficiency. These gearboxes are characterized by their straight-through design, where the input and output shafts are aligned in the same direction. This arrangement allows for smooth power transmission and makes in line gearboxes ideal for a variety of machinery, including conveyors, mixers, crushers, and pumps.

Working Principle

Gear Arrangement

The working principle of an inline gearbox is based on the gear arrangement within its housing. Typically, an inline gearbox consists of multiple gears arranged on parallel shafts. The input shaft is connected to a driver, such as an electric motor or engine, while the output shaft transmits power to the driven equipment.

The gears within the gearbox are designed to mesh perfectly, ensuring minimal friction and wear. The gears can be of various types, including spur gears, helical gears, and herringbone gears, each offering unique advantages in terms of efficiency, noise reduction, and torque capacity.

Power Transmission

When the input shaft rotates, it drives the first gear, which in turn drives the second gear, and so on, until the final gear on the output shaft rotates. This sequential gear engagement allows for a wide range of speed reductions or increases, depending on the gear ratios selected.

In line gearboxes can also incorporate multiple stages of gears to achieve higher ratios. Each stage multiplies the reduction or increase in speed, enabling the gearbox to provide a wide range of output speeds and torques to meet specific application requirements.

Advantages

Reliability and Durability

One of the key selling points of in line gearboxes is their reliability and durability. The simple, straight-through design minimizes moving parts and complex assemblies, reducing the likelihood of failures and maintenance requirements. The gears are precision-engineered to withstand high torques and speeds, ensuring long-term performance in demanding environments.

Efficiency

In line gearboxes are known for their high efficiency, with typical efficiency ratings exceeding 90%. This high efficiency is due to the precision gear meshing and minimal friction losses within the gearbox. The efficient power transmission results in lower energy consumption and reduced operating costs.

Compact Design

The compact design of in line gearboxes makes them ideal for space-constrained applications. The parallel-shaft arrangement allows for a smaller footprint compared to other gearbox types, such as right-angle gearboxes. This compact design also facilitates easier installation and integration into existing machinery.

Versatility

In line gearboxes offer a high degree of versatility, with multiple configurations and options available to suit various applications. Different gear ratios, input and output shafts, and mounting arrangements can be customized to meet specific requirements. Additionally, in line gearboxes can be combined with other components, such as motors and brakes, to create a complete drive system.

Noise Reduction

Helical and herringbone gears within in line gearboxes are designed to reduce noise and vibration. The curved teeth of these gears provide a smoother engagement, minimizing the impact and noise generated during operation. This noise reduction is particularly beneficial in applications where quiet operation is crucial, such as in healthcare and food processing facilities.

Maintenance-Friendly

In line gearboxes are designed for easy maintenance and serviceability. The housing can be easily opened to access the gears and bearings for inspection, lubrication, and repair. This accessibility reduces downtime and maintenance costs, ensuring that the gearbox remains in optimal condition for extended periods.

Conclusion

In conclusion, Wuxi UpperPeak Drive Equipment's in line gearboxes offer a reliable, efficient, and versatile solution for power transmission in industrial and mechanical applications. Their simple design, compact footprint, and high efficiency make them ideal for a wide range of machinery, from conveyors to crushers. With their ability to withstand high torques and speeds, in line gearboxes provide long-term performance and durability, reducing maintenance requirements and operating costs. Whether you're looking for a standard gearbox or a custom-configured solution, Wuxi UpperPeak Drive Equipment's in line gearboxes offer a robust and reliable choice for your power transmission needs.

https://www.uppdriver.com/working-principle-and-advantages-of-in-line-gearbox.html